3D printing is a shining example of innovation in the rapidly changing field of technology, turning digital designs into actual products with unmatched accuracy and productivity. The uses of 3D printing are as varied as they are endless, ranging from the production line to the artist's studio and offering an infinite future of personalization and inventiveness. We set out on a quest to learn everything about 3D printing in this comprehensive guide, from how do 3d printers work to its origins to its profound effects in a wide range of industries.

What is 3D Printing?

3D printing, also known as additive manufacturing, represents a paradigm shift in creating objects. In contrast to conventional subtractive manufacturing techniques, which involve removing material from a solid block, 3D printing constructs objects from the bottom up, layer by layer. This additive method provides versatility and creative freedom, simplifying the creation of elaborate structures and complex shapes.

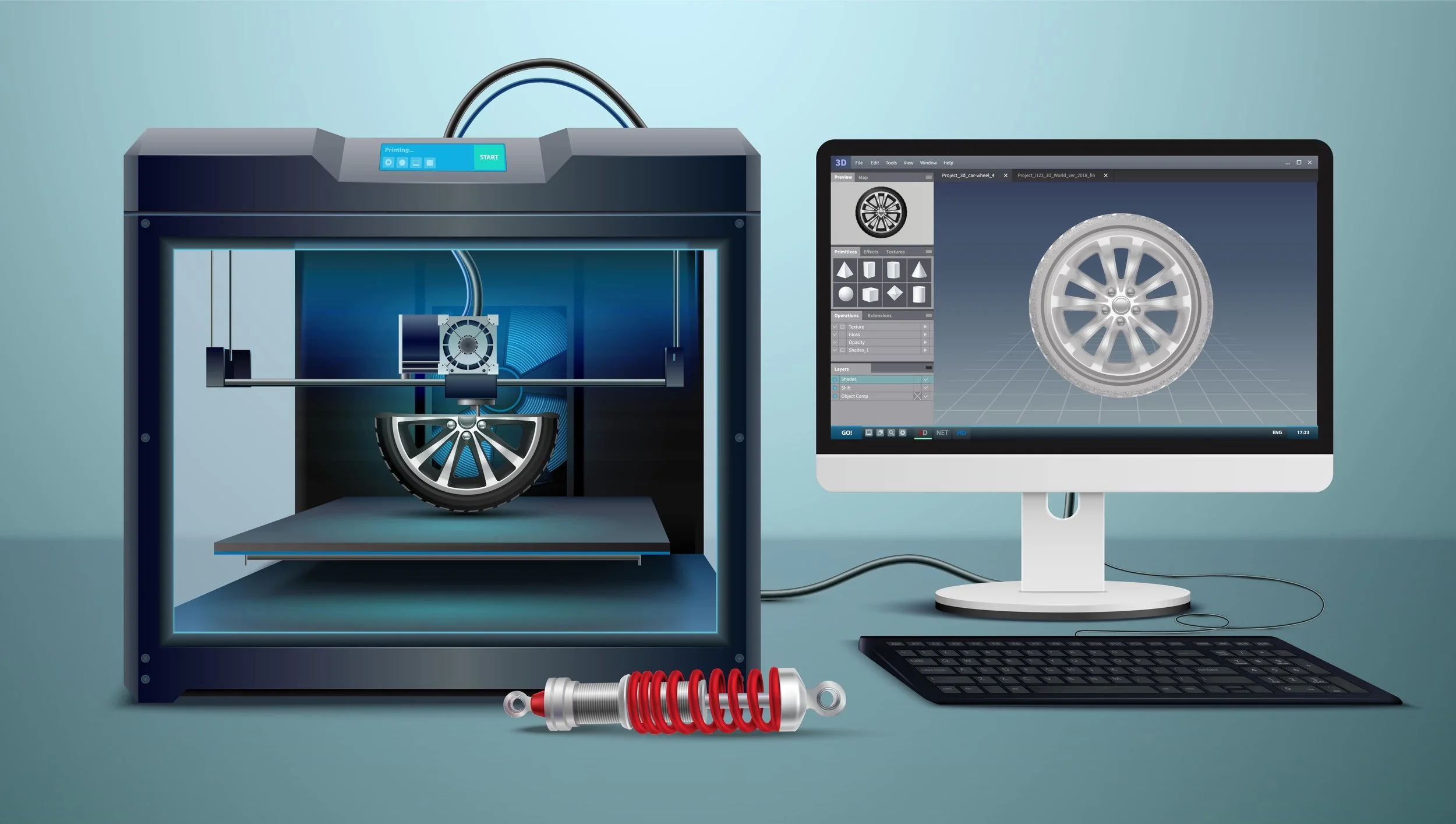

How Do 3D Printers Work?

The intricate interaction of materials, technology, and software is the basis of 3D printing. The process typically begins with creating a digital 3D model using Computer-Aided Design (CAD) software. After that, slicing software creates instructions for the 3D printer by cutting this digital blueprint into thin horizontal layers. The printer then carefully follows the directions from the slicing software, depositing or solidifying material layer by layer until the desired object is entirely produced.

When Was 3D Printing Invented?

The roots of 3D printing can be traced back to the 1980s when Chuck Hull invented stereolithography (SLA). This pioneering technology laid the foundation for additive manufacturing as we know it today. Since then, various additive manufacturing methods have surfaced, each with unique advantages and uses, opening up new horizons for the 3D printing industry.

Types of 3D Printing

1. Material Extrusion (FDM)

One of the most popular and easily accessible 3D printing methods is fused deposition modeling (FDM), a material extrusion. Thermoplastic filaments are heated in FDM printers and are pushed layer by layer via a nozzle to make objects. This approach is popular because it is easy to use, inexpensive, and versatile, making it appropriate for various tasks, including do-it-yourself projects and quick prototyping. This is also the most affordable and common method in 3d printing offering a variety of material and color options.

2. Stereolithography (SLA)

Stereolithography (SLA) utilizes a liquid resin cured by ultraviolet (UV) light to create precise, high-resolution models. SLA printers use a laser or projector to harden the resin layer by layer, producing prints with a beautiful, smooth surface finish and lots of detail. Applications for this technique can be found in fields where precise details and elaborate designs are crucial, like dentistry, jewelry, and the manufacture of medical devices.

3. Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) represents the advanced 3D printing technology, offering unparalleled speed, precision, and part quality. MJF is a technology developed by HP that applies a fusing agent selectively to a powdered material bed. The particles are then fused using an energy source, usually infrared light. This technology is perfect for various industrial applications since it can produce end-use parts with exceptional mechanical qualities, surface polish, and functioning prototypes.

What Can You Print With 3D Printers?

The versatility of 3D printing extends to various applications across various industries and disciplines. Some common objects that can be printed include:

Phone Stands and Organizers: Custom-designed accessories to keep your devices organized and within reach.

Small Plastic Objects: From household gadgets to toys and trinkets, 3D printing allows for easy, rapid prototyping and production of small plastic components.

Architectural Models: Architects and designers use 3D printing to create detailed scale models of buildings and structures for visualization and presentation, enabling stakeholders to understand better and engage with the design concepts.

Medical Devices: The healthcare industry harnesses 3D printing to produce patient-specific implants, prosthetics, surgical guides, and anatomical models for preoperative planning and training, revolutionizing patient care and surgical outcomes.

Arts and Crafts: Artists and creators explore the artistic potential of 3D printing to bring their imaginative designs to life, from sculptures and installations to wearable art and fashion accessories, pushing the boundaries of creativity and expression.

Personalized Gifts: With 3D printing, you can customize gifts and keepsakes, such as jewelry, figurines, and photo frames, to commemorate special occasions and create lasting memories for your loved ones.

Educational Materials: Teachers and educators utilize 3D printing to create interactive learning aids, models, and prototypes, enhancing student engagement and comprehension across various subjects and disciplines.

What Industries Use 3D Printing Technology?

The adoption of 3D printing spans various industries, each benefiting from its unique capabilities and advantages. Some key sectors that leverage 3D printing technology include:

Aerospace: By using 3D printing to prototype and quickly produce lightweight, complicated parts like engine parts, turbine blades, and structural components, the aerospace sector can reduce costs while increasing performance and fuel economy.

Automobiles: Manufacturers use 3D printing to quickly create tools, customize products, and manufacture spare parts on demand. This streamlines production procedures cuts lead times, and promotes more creative and flexible design.

Healthcare: 3D printing revolutionizes healthcare by providing personalized solutions, promoting medical research, and improving patient outcomes through tailored therapy and surgery planning. Applications range from patient-specific medical equipment and implants to bio-printed tissues and organs.

Fashion and Jewelry: By using 3D printing, designers and jewelers can produce complex, bespoke creations that go beyond the limits of conventional craft and aesthetics. This allows the fashion and luxury goods sectors to be more innovative, sustainable, and creative.

Architecture and Construction: Design exploration, optimization, and cooperation in the built environment become easier for architects and engineers by using 3D printing to prototype architectural models, building components, and construction tools quickly.

Leverage Customized 3D Product Solutions From KC Proto

Here at KC Proto, we're experts in creating personalized 3D printing solutions that meet your unique demands. Our modern technology and experience enable you to realize your ideas accurately and efficiently, whether as a product designer, engineer, or hobbyist. We offer extensive services to support your project from conception to completion, from low-volume production and custom fabrication to quick prototyping and functional testing. To learn more about how we can assist you in realizing your dreams and utilizing 3D printing technology to its fullest, contact us now.

FAQ’s

-

3D printing materials range from plastics and resins to metals, ceramics, and even biomaterials. Common materials include PLA, ABS, PETG, nylon, resin, stainless steel, titanium, and biocompatible polymers.

-

Yes, 3D printing can be used for manufacturing finished products, although it may be more suitable for low-volume production, customized items, and complex geometries. Aerospace, automotive, and healthcare industries increasingly utilize 3D printing for end-use parts and components.

-

The advantages of 3D printing include design freedom, rapid prototyping, customization, waste reduction, supply chain efficiency, and revolutionizing manufacturing methods.

-

Common file formats for 3D printing include STL (stereolithography), OBJ (object), and AMF (additive manufacturing format). These formats encode the geometry and topology of 3D models, allowing them to be interpreted by slicing software and translated into printable instructions.

-

3D printing technology has become increasingly accessible to individuals and hobbyists in recent years, thanks to affordable desktop printers, user-friendly software, and online resources. From DIY enthusiasts to educators and entrepreneurs, anyone can harness the power of 3D printing to unleash their creativity and innovation.